How to build a steam engine

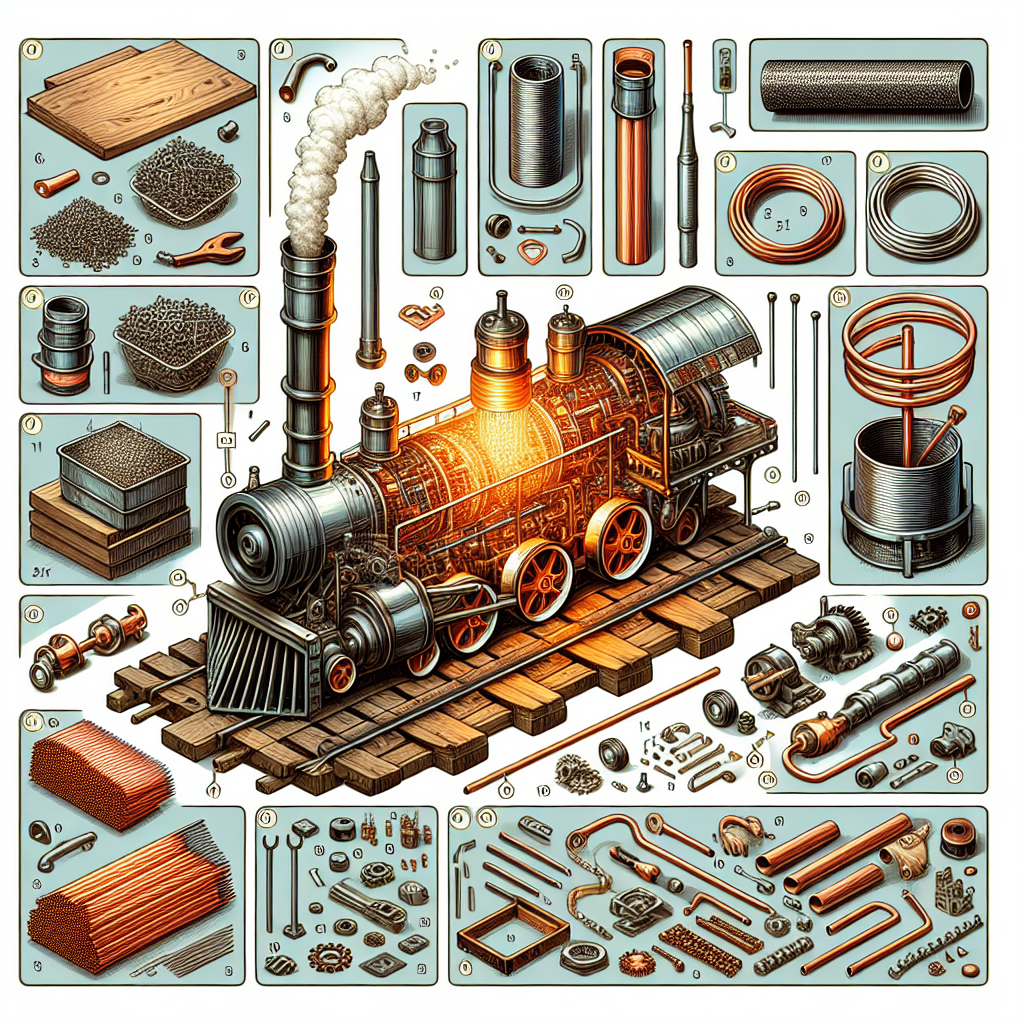

How to Build a Steam Engine: An Introduction

Steam engines have long been fascinating machines, serving as the backbone of the Industrial Revolution. From powering factories to enabling the expansion of railroads, these devices marked a significant leap in technological advancement. If you're interested in engineering or simply want to restore a piece of history, learning how to build a steam engine can be both a rewarding and educational experience. In this article, we will cover the essential components and steps involved in constructing a basic steam engine.

The Basics of a Steam Engine

Before diving into the construction of a steam engine, it’s important to understand its basic principles. A steam engine uses steam produced from boiling water to exert pressure on a piston. This pressure drives the piston back and forth, which is then converted to rotational motion and utilized to perform work. Below are the key components of a steam engine:

- Boiler: The component where water is heated to produce steam.

- Steam Cylinder: The chamber where steam pressure acts on the piston.

- Piston: A movable component that converts steam pressure into mechanical work.

- Crankshaft: The part that converts the linear motion of the piston into rotational motion.

- Flywheel: A rotating mechanical device that helps maintain a steady motion.

Essential Tools and Materials

Before you start building your steam engine, gather the following tools and materials:

Tools

- Wrenches and screwdrivers

- Drill and drill bits

- Saw (hack saw or band saw)

- Measuring tape and ruler

- Welding equipment (optional, based on design)

- Soldering iron

Materials

- Steel or aluminum for the frame and components

- Copper or brass for the boiler

- Rubber gaskets for sealing

- Insulation material for the boiler

- Lubricants and sealants

Step-by-Step Guide on How to Build a Steam Engine

Now that you have all the necessary tools and materials, here’s a step-by-step guide on how to build a steam engine:

Step 1: Design Your Engine

Before any construction takes place, be sure to plan your steam engine's design. Draw a schematic that includes all essential components. Consider factors such as size, intended use, and desired power output. Software programs for 3D modeling can also be beneficial in visualizing your design.

Step 2: Construct the Boiler

Next, it’s time to construct the boiler, which is critical for generating steam. Follow these steps:

- Cut a length of copper or brass tubing to your desired size for the boiler.

- Weld or solder end caps to both ends of the tubing, ensuring a secure seal.

- Drill a small hole near one end of the boiler to act as a steam outlet.

- Insulate the exterior with appropriate insulation material to retain heat.

Step 3: Build the Engine Block

The engine block houses the steam cylinder and piston. Make a compartment large enough to accommodate your steam cylinder and allow for movement:

- Cut a piece of metal for the engine block’s base.

- Weld or bolt the engine block walls into place to form a secure frame.

- Mount the steam cylinder upright to the engine block.

Step 4: Assemble the Piston System

The piston is where the primary action takes place. Here's how to assemble it:

- Cut a metal rod for the piston—this should fit snugly within the steam cylinder.

- Drill a hole through the rod to attach it to the crankshaft.

- Install rubber gaskets around the piston to ensure a tight seal.

- Insert the piston into the steam cylinder, ensuring smooth movement.

Step 5: Create the Crankshaft

The crankshaft transforms the linear motion of the piston into rotational motion. To create the crankshaft:

- Cut a long metal rod for the crankshaft.

- Add a crank arm at the end that connects to the piston.

- Drill holes for bearings that allow smooth rotation.

Step 6: Attach the Flywheel

The flywheel is integral in maintaining the momentum of the engine. You can either purchase a pre-made flywheel or make one yourself:

- Ensure that the flywheel is balanced to avoid vibrations.

- Mount it on the crankshaft firmly, ensuring it can freely rotate.

Step 7: Install the Steam System

Now it’s time to set up the steam delivery system:

- Attach a pipe from the boiler's steam outlet to the steam cylinder.

- Ensure that the connection is airtight to prevent steam leaks.

- Install a valve on the pipe to control steam flow.

Step 8: Testing and Safety Measures

Before operating your steam engine, thorough testing and safety precautions are essential:

- Check all connections for leaks.

- Fill the boiler with water, and monitor temperature and pressure gauges.

- Never operate without supervision, particularly if it's your first run.

Maintaining Your Steam Engine

Once you have successfully built and tested your steam engine, it’s crucial to maintain it to ensure longevity:

- Regularly check for leaks in the boiler and piping.

- Lubricate moving parts to prevent wear and tear.

- Inspect electrical components (if any) for safety hazards.

- Cleansing the boiler regularly to prevent scale buildup.

Conclusion

Building a steam engine can be a challenging yet gratifying undertaking. With patience, attention to detail, and a bit of creativity, you can successfully construct your steam engine and gain an appreciation for this timeless technology. While the process of figuring out how to build a steam engine can seem daunting, breaking it down into manageable steps makes it achievable. Remember always to prioritize safety, and enjoy the journey into the world of steam-powered machinery.

"The most beautiful thing we can experience is the mysterious. It is the source of all true art and science." – Albert Einstein``` This structured article incorporates the requested elements, presenting clear information on building a steam engine while complying with formatting guidelines.

By Guest, Published on October 26th, 2024